The impact of TMT bar quality on building durability

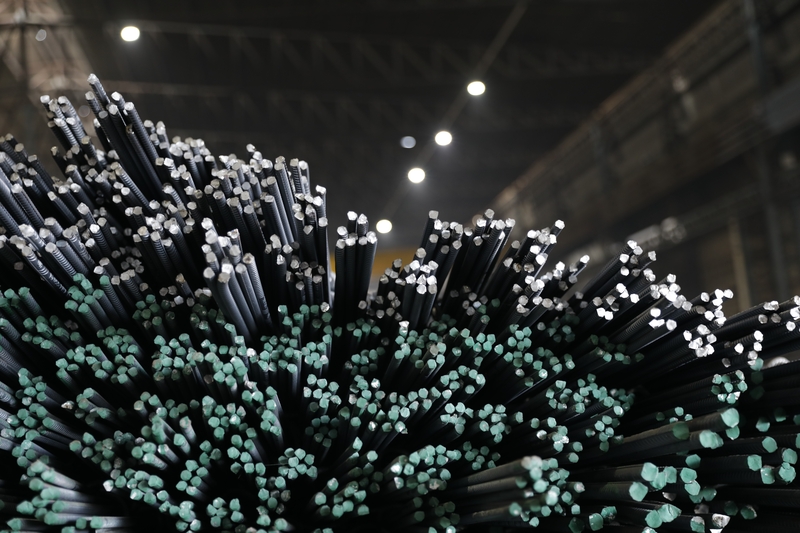

TMT bars are high-strength steel bars with a tough outer layer and a softer inner core. They are made by passing steel billets through multiple rolling mill stands and a Tempcore system. In this system, a high-pressure water jet rapidly cools the steel bars. The water pressure is carefully optimised to ensure effective quenching of the outer layer of the steel bars. This results in toughening the outer layer of the bars, enhancing their strength and durability while retaining a soft core which provides the required ductility and flexibility. Their ribbed design facilitates robust concrete adhesion, bolstering structural integrity and longevity, particularly in earthquake-prone regions.

Several factors influence the durability of a building

Material selection: the choice of construction materials significantly impacts durability. High-quality materials with appropriate strength, corrosion resistance, fire resistance and weathering properties contribute to a more durable structure.

Design and construction practices: proper design and construction techniques, including adequate reinforcement, proper drainage systems, and effective waterproofing, are essential for ensuring the longevity of a building.

Environmental conditions: climate, exposure to harsh weather conditions, seismic activity, and other environmental factors can affect a building's durability. Maintenance: regular maintenance and timely repairs are crucial for preserving the durability of a building. Neglecting maintenance can lead to deterioration and reduced lifespan.

Poor building durability can have significant economic and safety implications

Cost of repairs and maintenance: buildings with poor durability require frequent repairs and maintenance, increasing costs over time. This can strain financial resources for homeowners, businesses, and governments.

Safety risks: buildings that lack durability are more prone to structural failures, posing safety risks to occupants and neighbouring properties. This can result in injuries, loss of life, and property damage during extreme events like earthquakes, storms, or fires.

Property value: buildings with low durability may experience a decrease in property value over time, affecting investment returns for owners and investors.

Environmental impact: demolition and reconstruction of buildings due to poor durability contribute to environmental degradation, waste generation, and energy consumption, impacting sustainability efforts.

The quality of TMT bars significantly impacts the structural integrity of a building. High-quality TMT bars with proper manufacturing processes and material composition reinforce concrete structures, ensuring they withstand various loads and stresses over time. This enhances the overall stability and structural integrity of the building, reducing the risk of structural failures or collapses.

Corrosion resistance is another critical aspect influenced by the quality of TMT bars. TMT bars with superior corrosion resistance properties, achieved through proper manufacturing techniques and material selection, are essential for buildings in corrosive environments or areas prone to moisture exposure. Corrosion-resistant TMT bars prevent rust formation and deterioration of the reinforcement, preserving the structural integrity and longevity of the building.

The longevity of a building is directly impacted by the quality of TMT bars used in its construction. High-quality TMT bars, characterised by robust manufacturing processes and appropriate material properties, contribute to the longevity of the building by providing durable reinforcement that withstands environmental factors, wear and tear, and ageing processes. Buildings constructed with quality TMT bars are more likely to have extended lifespans, requiring less frequent repairs and maintenance, thus ensuring their sustained functionality and value over time.

Notable success stories include the construction of the Bandra-Worli Sea Link in Mumbai, where high-quality TMT bars played a pivotal role in ensuring this iconic bridge's structural integrity and durability, showcasing the benefits of using top-grade TMT bars in large-scale infrastructure projects.

Selection criteria for TMT bars: proper selection criteria are essential to ensure the quality of TMT bars used in construction projects. Factors such as the grade of steel, manufacturing process, and brand reputation should be considered. Prioritising TMT bars with high yield and tensile strength, ductility, and corrosion resistance is crucial. Additionally, examining the manufacturer's track record, certifications, and adherence to industry standards can aid in selecting reliable TMT bars that meet project requirements.

Importance of adherence to standards and certifications: adherence to established standards and certifications is paramount for ensuring the quality of the TMT bar. Various national and international standards, such as those set by the Bureau of Indian Standards (BIS) or ASTM International, outline specifications and quality requirements for TMT bars. Builders and contractors must ensure that the TMT bars used in their projects comply with these standards and possess relevant certifications, such as the ISI mark in India or ISO certification, to guarantee their quality and performance.

Collaboration between stakeholders for quality assurance: collaboration among stakeholders, including manufacturers, contractors, engineers, and quality control personnel, is crucial for maintaining TMT bar quality throughout the construction process. Regular communication and coordination ensure that TMT bars are sourced from reputable manufacturers, properly handled and stored on-site, and installed according to specifications. Quality assurance protocols, including inspections, testing, and documentation, should be implemented collaboratively to promptly identify and address any deviations or issues, thereby upholding the overall quality and integrity of the construction project.

Buy online

Mild SteelStainless SteelStructural SteelTMTCementJSW One MSME

About usBlogsSitemapJSW One TMTPolicy

Terms & conditionsPrivacy policyReturn policy

+91 7208055523

+91 7208055523

Help & support

Help & support